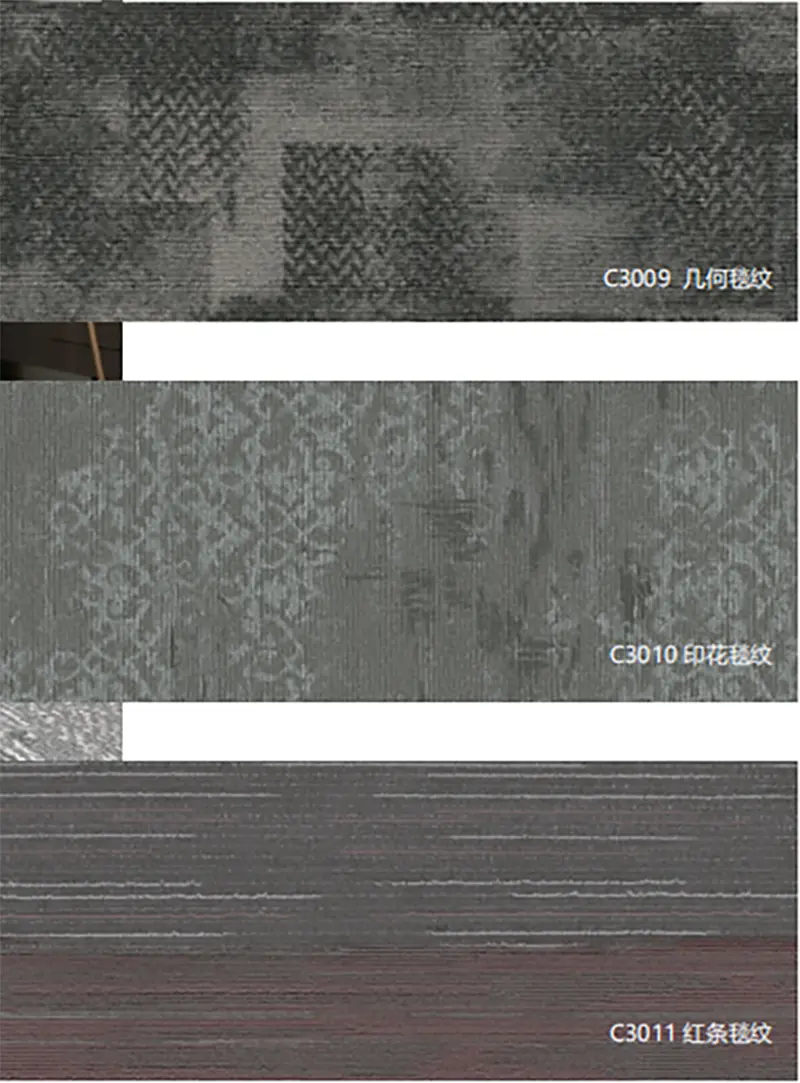

SPC Flooring Carpet Grain

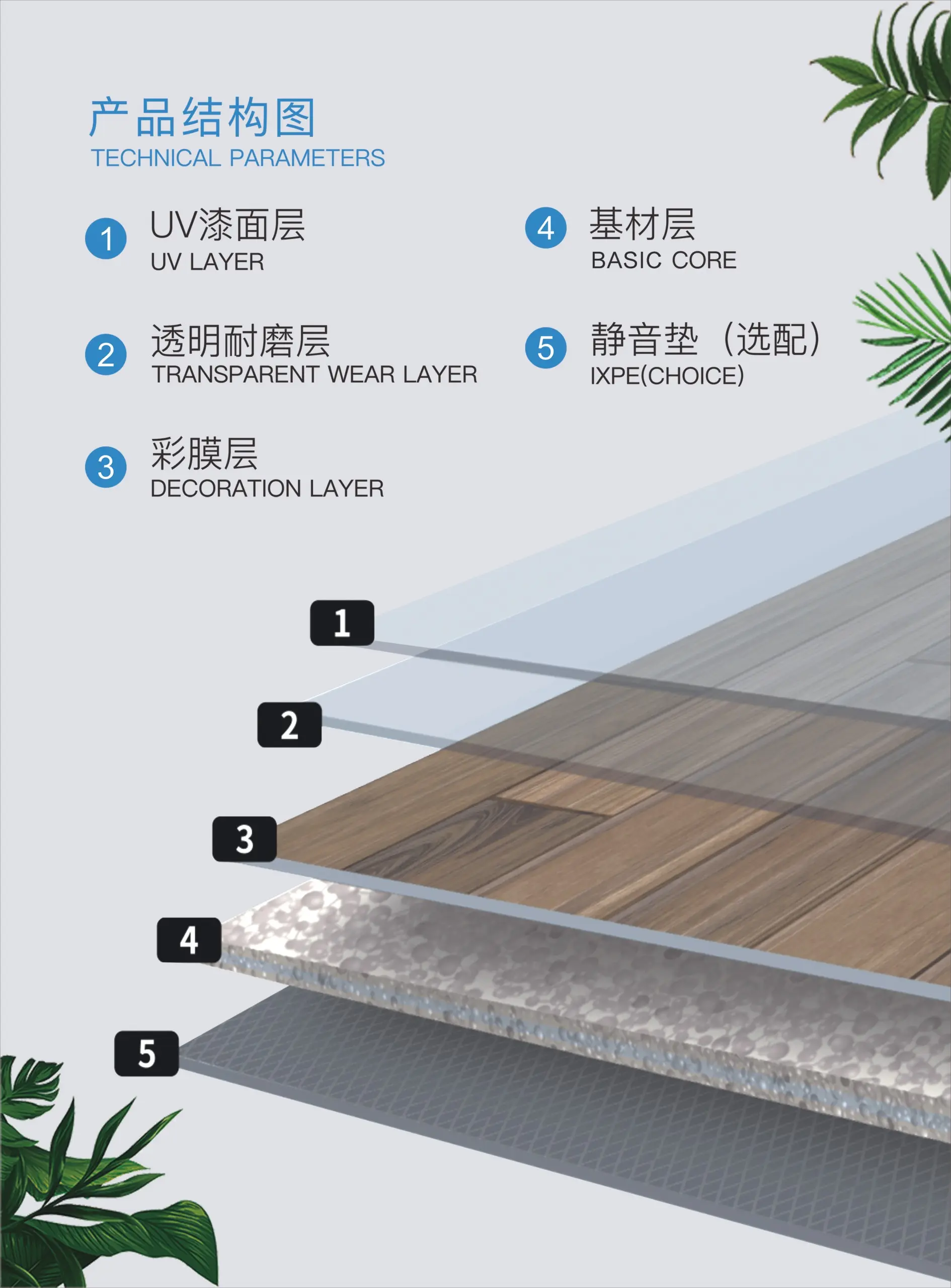

SPC Flooring’s IntroductionStone plastic composite flooring, SPC flooring, is a new type of high-quality ground decoration material. It adopts natural marble powder to form a solid base with high-density and high fiber mesh structure, and its surface is covered with super wear-resistant polymer ethylene wear-resistant layer, which is processed through hundreds of processes. Polyvinyl chloride resin is an environmentally friendly, non-toxic and renewable material.

WhatsApp Now